Yacht Wrapping Bible (eBook)

The Ultimate Guide to Yacht Wrapping by LuxWrap®

This eBook is a practical guide for yacht owners, captains, crew, and managers planning wrapping projects. It reviews each application—covering purpose, preparation, materials, challenges, solutions, contractor choice, and examples—so readers gain the knowledge needed for performance, durability, and finish quality.

Summary Overview

Yacht wrapping has developed into a highly specialised field within the marine industry, providing both aesthetic and protective solutions across a wide range of vessel types.

Applications extend well beyond simple colour changes and now include structural finishes, high value surface preservation, and interior refitting with architectural films.

In this guide, we introduce the key categories of yacht wrapping and marine protection, with in-depth coverage to follow in the chapters below.

Overview - Hull Wrapping

Hull wrapping is the most recognised application and immediately springs to mind when one thinks about yacht wrapping. It offers an alternative to paint for full-colour change, temporary finishes, or preservation of an existing coating system.

Common objectives include:

- Colour change – replacing or trialling new colourways without committing to a full paint programme.

- Preservation – shielding an existing paint system to extend its service life.

- Interim refresh – restoring appearance to defer a scheduled repaint by several seasons.

Technical considerations include substrate preparation, yard staging requirements, and the choice of marine-grade films with a real-world track record in the marine environment. Vessel size, shape and detailing dictate both installation complexity and the level of contractor expertise required.

Overview - Superstructure Wrapping

Superstructures, and particularly the external areas of superstructures are highly susceptible to UV degradation and gloss reduction. Wrapping provides a method of restoring or altering appearance while maintaining operational availability of the vessel.

Applications typically involve:

- Matching or contrasting the hull finish.

- Replacing or covering faded paint/coatings with a similar tone.

- Highlighting structural details for visual definition.

Due to the number of complex edges, joins, and compound curves within a superstructure, wrapping requires advanced installation skill. Poor workmanship is particularly visible in these areas, making contractor capability a critical factor in achieving a durable and seamless result.

Overview - Accent Wrapping and Deckheads

Targeted wrapping of exterior accents can quickly modernise the profile of a vessel. A common example is the blackening of superstructure areas between windows in order to unify glazing lines and update styling, giving the impression of larger windows.

Deckhead wrapping is also a proven alternative to conventional paint, particularly where reduced downtime, minimal mess, and lower cost are priorities. When installed correctly, films deliver a smooth and uniform finish with the advantage of reversibility.

Overview - Interior Wrapping

Interior wrapping employs architectural films engineered for abrasion resistance, chemical durability, and long-term adhesion in high-use environments. These films enable transformation of interior spaces without the disruption of traditional refit processes.

Typical applications include:

- Wall panels cupboards/doors.

- Furniture refurbishment.

- Surface modernisation aligned with an owner’s palette or in consultation with interior designers.

The technical benefits include rapid installation, minimal dust and odour, and a broad range of finishes (woodgrains, metallics, stones, or solid colours) with proven resistance to knocks and wear.

Overview - Surface Protection Films

Surface protection films such as NinjaShield® are increasingly specified as a preventive measure to extend the service life of both interior and exterior finishes.

- Interior protection films safeguard stainless steel, refrigeration units, bar tops, laundry equipment, and high-value marble surfaces from scratching and wear. Additionally, the films increase hygiene and significantly ease cleaning..

- Exterior marine protection films provide sacrificial shielding to hull sections, cap rails, high-traffic zones, varnished wood, and polished metal surfaces.

These films are optically clear and available in gloss, matt and satin finishes, engineered for UV stability, and designed for easy removal or replacement at the end of service life.

“This chapter and its contents are part of the eBook Yacht Wrapping Bible -The Ultimate Guide to Yacht Wrapping by LuxWrap® and are the intellectual property of LuxWrap Group Limited. References and link-backs are permitted; however, unauthorised duplication or reproduction or plagiarism, in whole or in part, will be treated as a breach of copyright and pursued through legal action.”

📞 Contact LuxWrap Today

Tel: +44 (0)208 068 7468

🌐 www.luxwrap.com

Chapter 1 — Hull Wrapping

Hull Size Matters

"The World's Smallest Superyacht Wrap" (Miniature wrapped to match the main vessel wrap)

When people think of yacht wrapping, the hull is usually the first area that comes to mind. Yet the scope of a hull project can vary dramatically—from small powerboats at one end, to 100m+ mega yachts at the other.

This wide range in vessel size means that yacht wrapping projects can vary just as much as painting, fairing, or engineering work. Depending on a yacht’s size, tonnage, and value, the type of contractor required will also differ significantly. It is therefore vital to ensure that any contractor quoting the work understands how to survey and quote a vessel of the relevant size and has successfully delivered similar projects before.

Preparation: An Important Point

Importance of Surface Condition

"In simple terms: the cleaner and smoother the surface, the better the end result."

Vinyl has no filling properties; scratches, cracks, or dings will show through. More importantly, any area that allows water ingress must be repaired before wrapping; likewise flaking or exfoliating paint cannot be wrapped and would need to be sanded back to a sound surface.

A practical approach is to assign one crew member to inspect the hull in advance, mark defects with blue tape, and then ensure they are ground out if necessary, filled and sanded. This small, inexpensive task can be the difference between a wrap completed on time and budget, or one delayed by days of unexpected surface repairs.

Infrastructure and logistics

"Access and support equipment are extremely important to plan in advance."

Crew should communicate early with both the wrap contractor and shipyard to confirm that all infrastructure—such as rafts, ladders, planks, scissor lifts, or cherry pickers are arranged and ready before the installation team arrives.

Through our years of experience wrapping yachts of all shapes and sizes—and every level of complexity—the LuxWrap team has developed exceptional improvisational ability: if it’s physically possible, we’ll make it happen.

Communication is key

"LuxWrap always outline the necessary requirements well in advance to ensure a smooth process."

Whilst we understand that preparation is sometimes delayed or incomplete, and we will assist where necessary, this inevitably adds cost compared to having the crew or yard complete the work beforehand.

The key takeaway is that clear communication and thorough preparation are essential. When expectations are aligned on both sides, projects are far more likely to be delivered efficiently, cost-effectively, and to the highest standard.

Materials: A General Point

"A large wrapped yacht tackling the high-seas."

Material choice is critical, regardless of vessel size. Contrary to what some assume, it is not wholly dependent on brand name.

Large brands have often shown inconsistent quality and varying durability across different colours, while certain lesser-known manufacturers have, in our experience (as pictured above), demonstrated superior performance crossing oceans multiple times.

For neutrality, we will not list specific brands here. It is enough to say that whatever material is recommended should have real-world proof of durability beyond just a brand name. When you contract LuxWrap for high-end installations, you can rest assured that we have real world examples of virtually every type of material on all shpaes and sizes of vessels.

It must also be understood that vinyl is not as durable as paint. As we have always said, vinyl complements paint—it does not replace it. Setting expectations with this in mind is vital.

Hulls Below 20 Meters

Why wrap yachts under 20m?

"Owners of smaller yachts often choose wrapping as a cost-effective alternative to painting."

Sometimes it is for styling—a particular colour that can be reversed at resale. Other times it is simply because a full repaint or gelcoat is not worth the investment, but they still want the yacht to look attractive until sold.

How are SMALLER yachts wrapped?

"Custom built GTB receiving satin brown/gold wrap, indoors with scissor lift."

Vessels up to 20m are typically wrapped on hard standing, with installers using fixed scaffolding erected by the yard or scissor lifts. Our preference is always lifts, as they enable more efficient working, though some may prefer scaffolding.

Pros and cons of wrapping sub 20 meter yachts

"Example of small yacht's position during full colour change wrap."

It is vital to understand that smaller yachts tend to be tightly moored alongside other boats and are more exposed to knocks and scrapes. Naturally any such damages will be more visible on a smaller boat, which can shorten the wrap’s 'looking good' lifespan.

For this reason, we almost always recommend applying a paint protection film (PPF), such as NinjaShield®, on top of the vinyl. While this increases cost, it extends durability and produces a higher gloss finish.

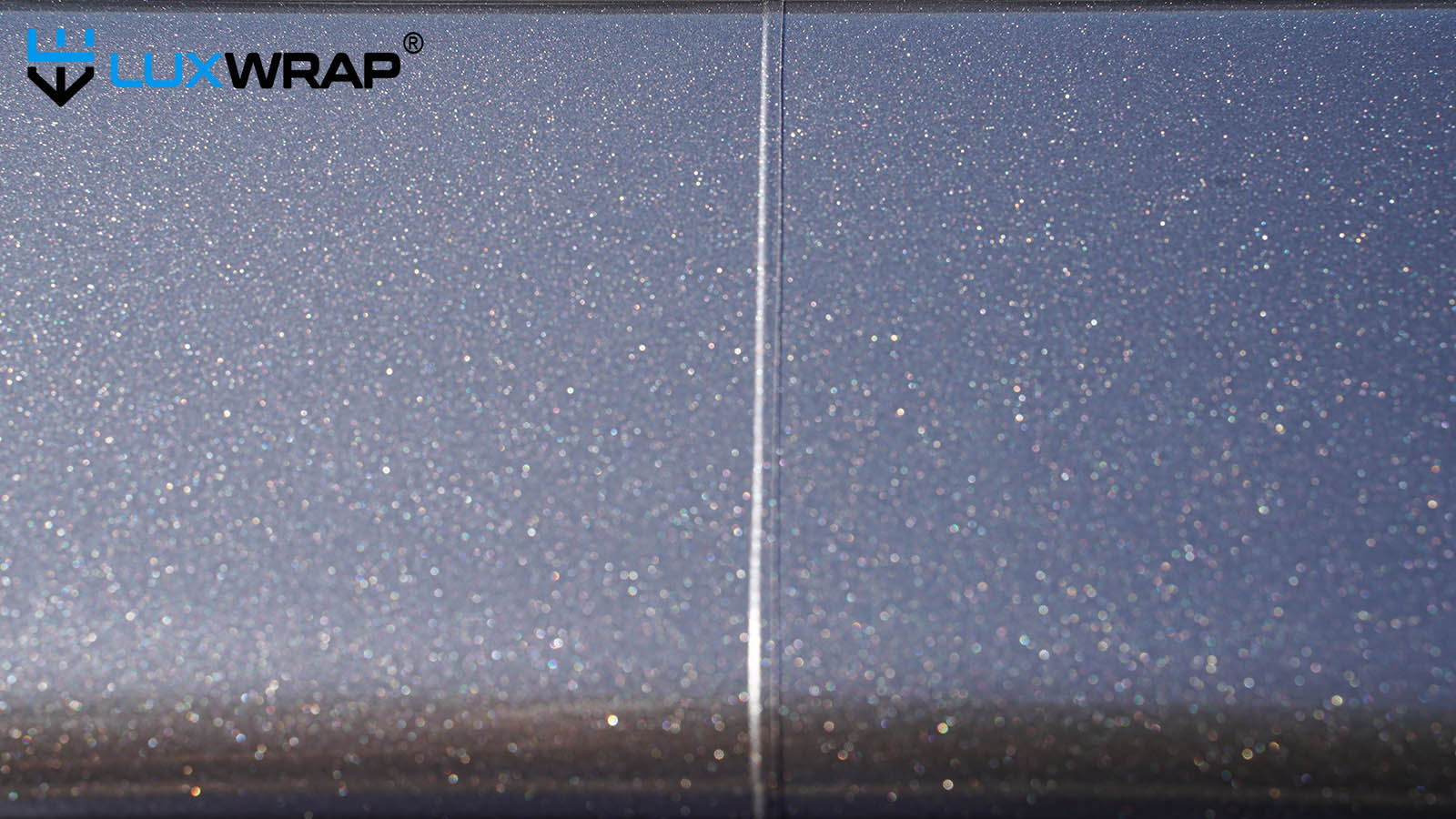

"Hard wearing high gloss finish of NinjaShield® Paint & Surface Protection Film."

The only drawback in applying PPF on a yacht hull of any size, is that requires more manpower and skill than vinyl alone, due to differences in installation technique and material properties. This is one reason why some owners may prefer to hire a specialist company like LuxWrap with experience in both vinyl and PPF.

Who should you hire?

For hulls up to 20m, many competent local wrap shops can deliver an acceptable job. It may not always be cost-effective to fly in an international specialist such as LuxWrap. Regardless of choice, best practice is to check portfolios, request photos and references, and ask about the materials used, as well as for examples of how they have performed in real-world conditions.

Hulls 30–60 Meters

Why wrap a superyacht instead of paint?

"Yacht owner chooses to complete a full colour change wrap instead of painting."

Captains and crew often ask: “Why wrap something this big and not paint it?” The answer lies in time and cost. Painting yachts in this size bracket involves very high expense and months of downtime.

Some owners prefer to avoid this cost altogether, while others know it will be necessary eventually but want to delay until a planned survey or refit. Yet others still want to try out a new colour before deciding if they really want to commit to it in paint.

"Superyacht explores a new colour with LuxWrap."

A common scenario is a vessel which might be a few years from its five-year survey, where the paintwork is already tired. If the yacht is busy with charters, appearance matters.

"Another superyacht wraps to refresh look instead of painting."

Wrapping can provide a paint-like finish that lasts several years, at a fraction of the cost of painting, and generally with installation in the water. In some cases, we have wrapped vessels afloat for less than the cost of hauling them out.

How are larger yachts wrapped?

"Cherry pickers and floating pontoons are standard practice on yachts above 40 meters"

Quoting and executing a 40m+ hull wrap is very different from working on smaller boats, due to variations in tonnage and hull form.

Wrapping in the water can save significant shipyard costs, but very few contractors have the experience required to deliver at this scale. For an owner requiring this work, it is absolutely essential that the company hired can deliver the agreed works on budget and on schedule.

Considerations - Pros & Cons

Not every wrap is about a colour change. Many owners request wraps that match their existing paint. Sometimes an “off-the-shelf” vinyl will suffice; in other cases, custom colour-matched films must be manufactured—feasible only on larger yachts where minimum order requirements can be met.

One consideration with colour changes is visibility of underlying paint in the event of damage. For example, a dark wrap over a white hull will reveal white if scraped. These areas can be patch repaired, and we often train crew in how to carry out such repairs. With colour-matched vinyl, such damage is virtually invisible.

In water vs. out of water

"Harness access is sometimes the only way to wrap those difficult-to-reach areas of yacht hull."

Wrapping afloat is often quicker and avoids many shipyard issues, provided weather and access are suitable. Yard-based projects, on the other hand, may involve larger equipment and can be slowed by dust, wind, and other third-party activity. Good results can be achieved in both environments, and the choice depends on management’s preference.

Who should you hire?

Above 40m, the financial stakes, deadlines, and ancillary costs increase significantly. A local wrap shop may be capable with smaller boats, but is unlikely to be considered reliable at this level.

Owners and managers should evaluate the market carefully, prioritising companies like LuxWrap, with a proven record of large-scale projects delivered by experienced, consistent teams.

Hulls 60-100 + meters

IT IS FAIR TO SAY THERE IS NO UPPER LIMIT ON SIZE

A growing number of mega-yachts are also choosing to wrap for a variety of reasons, the cost savings compared to painting can be substantial once vessels reach 100m+.

Similar to large superyachts, which are often wrapped to delay a repaint, the management of very large mega-yachts also consider hull wrapping to protect and preserve a brand-new paint job. This is usually done with vinyl or Paint Protection Film (PPF) or a combination of both, especially in high-traffic areas most prone to wear and tear.

Technical requirements

Projects on this scale demand additional competencies—references, track record, project planning, safe operation of large cherry pickers, working in harnesses at height, and managing complex access and logistics.

Examples.

- A 110m vessel contracted LuxWrap to protect the newly polished hull and garage doors from UV and abrasion. The solution was to install paint protection film in the relevant areas. The entire project was completed in the water.

- On a 120m+ vessel, management contracted LuxWrap to protect a newly painted, dark coloured hull from UV and abrasion. The solution combined colour-matched vinyl with PPF, creating a highly durable system which was installed in the water.

- A 68m charter yacht contracted LuxWrap, two years from its 5 year survey, requiring a colour-matched gloss refresh mid-season. Custom vinyl was produced, and the colour-matched wrap delivered the desired appearance without disrupting charter commitments. The vessel went on to cross the Atlantic Ocean several times.

Conclusion

Considering all of the above, hull wrapping is definitely not a "one-size-fits-all" service. It is clear that the scope and scale of hull wrapping projects is broad and varied, and therefore the approach must be adapted to vessel size, value, and operational needs.

For smaller yachts, wrapping offers a flexible and economical way to refresh or restyle appearance. For large superyachts, it provides a viable alternative to painting, bridging the gap between refits, reducing downtime, and maintaining aesthetic standards.

Whatever the size, the key is selecting a contractor with appropriate experience. For simple projects, local providers may be sufficient. For complex or high-value yachts, proven specialists like LuxWrap are essential.

Done well, yacht hull wrapping is a versatile and increasingly indispensable part of modern yacht maintenance and presentation—and LuxWrap, as a highly experienced leader in the field, continually sets the benchmark for how it should be done, no matter the shape, size or complexity.

“This chapter and its contents are part of the eBook Yacht Wrapping Bible: The Ultimate Guide to Yacht Wrapping by LuxWrap® and are the intellectual property of LuxWrap Group Limited. References and link-backs are permitted; however, unauthorised duplication or reproduction or plagiarism, in whole or in part, will be treated as a breach of copyright and pursued through legal action.”

📞 Contact LuxWrap Today

Tel: +44 (0)208 068 7468

🌐 www.luxwrap.com

Chapter 2 — Superstructure Wrapping

Scope of Works

Yacht Superstructures Wraps generally fall into two broad categories.

Yacht Superstructures Wraps generally fall into two broad categories.

At one end are the higher-tonnage yachts, often with several decks, (main, bridge, sundeck etc) with expansive surface areas, including removable deckheads and integrated fittings, and generally more complex detailing.

At the other end are the sleek, low-profile designs typical of smaller production yachts and open Mediterranean-style vessels.

We do fewer of these smaller-type projects now due to our focus on larger vessels, but we have completed many such installations over the years, and we are always happy to quote new projects in this category. In our opinion it benefits owners who want the highest level of workmanship with fair pricing from a contractor they know and trust.

Regardless of style, outer-facing surfaces exposed to the elements deteriorate far more quickly than inner faces or the hull itself. For this reason, a superstructure wrap is typically categorised as either Exterior-Only (outer surfaces only) or Full Superstructure (complete coverage inside and out).

The motivations for wrapping a superstructure mirror those of hull wrapping:

- Colour change for aesthetic preference.

- Delaying paintwork, usually due to UV degradation or fading.

Exterior Superstructure

An exterior-only superstructure wrap is common when interior paint remains sound, but the external white gloss has dulled. In this case, the wrap simply restores the outer appearance without needing to wrap interior finishes.

This type of project is relatively straightforward. Access is usually via the yacht’s decks, supplemented by cherry pickers or rope access in rare cases. Compared to a full superstructure wrap, exterior-only wraps require far less time, material.

Full Superstructure Wrap

A full superstructure wrap involves covering every external and internal facing element of the superstructure — not only what is visible from outside the yacht, but also what the crew and guests see while on board. This includes:

- Bulkheads, bulwarks, and gunwales.

- Cupboard and locker faces, built-in furniture bases

- Deckheads, mouldings, bar units, and sun deck structures.

In short, if an owner wishes to change the entire colour palette (e.g., from white to silver), a full wrap ensures that no trace of the original colour is visible when doors are shut and cushions are in place.

Superstructure Wrapping Guidelines

Preparation Requirements

As with hull wrapping, correct preparation is critical. Vinyl has no filling properties: defects, cracks, or cut lines will show through and any area prone to moisture ingress will compromise adhesion.

Additionally, we frequently encounter severe UV degradation which when combined with inadequate preparation during the last paint cycle means even masking tape can strip paint on removal. If not addressed, vinyl will lift these same areas during installation, leading to wasted time, wasted material, and frustration for crew, contractors, and ultimately the owner.

We recommend assigning a crew member to thoroughly inspect the entire superstructure prior to wrap contractors arrival. Defects should be marked with tape, then ground out, filled, and sanded to a smooth surface.

It is amazing what a few day workers with sanders can do in terms of ensuring the best possible end-result is achieved.

Correct preparation should eliminate:

- Overspray and old paint cut lines.

- Flaking or exfoliated coatings.

- Cracks, chips, dings, and blisters.

- Moisture-retaining defects.

Smaller repairs may be wrapped directly over filler if sanded to 400 grit smoothness, while larger areas are best primed. The key is consistency and smoothness across all visible surfaces.

Sikaflex Caulking

Vinyl cannot bond directly to Sikafle. A cut line must be placed 2–3mm away, with three common options for finishing:

- Remove and replace the caulking after wrapping.

- Apply a new bead over the joint to cover the old colour.

- Paint a narrow strip (~1 cm) around the Sikaflex in a matching colour before wrapping.

All Sikaflex work and fixture removal should be arranged separately, generally crew or day workers are better positioned to complete these works as they are time consuming and separate to the actual vinyl installation.

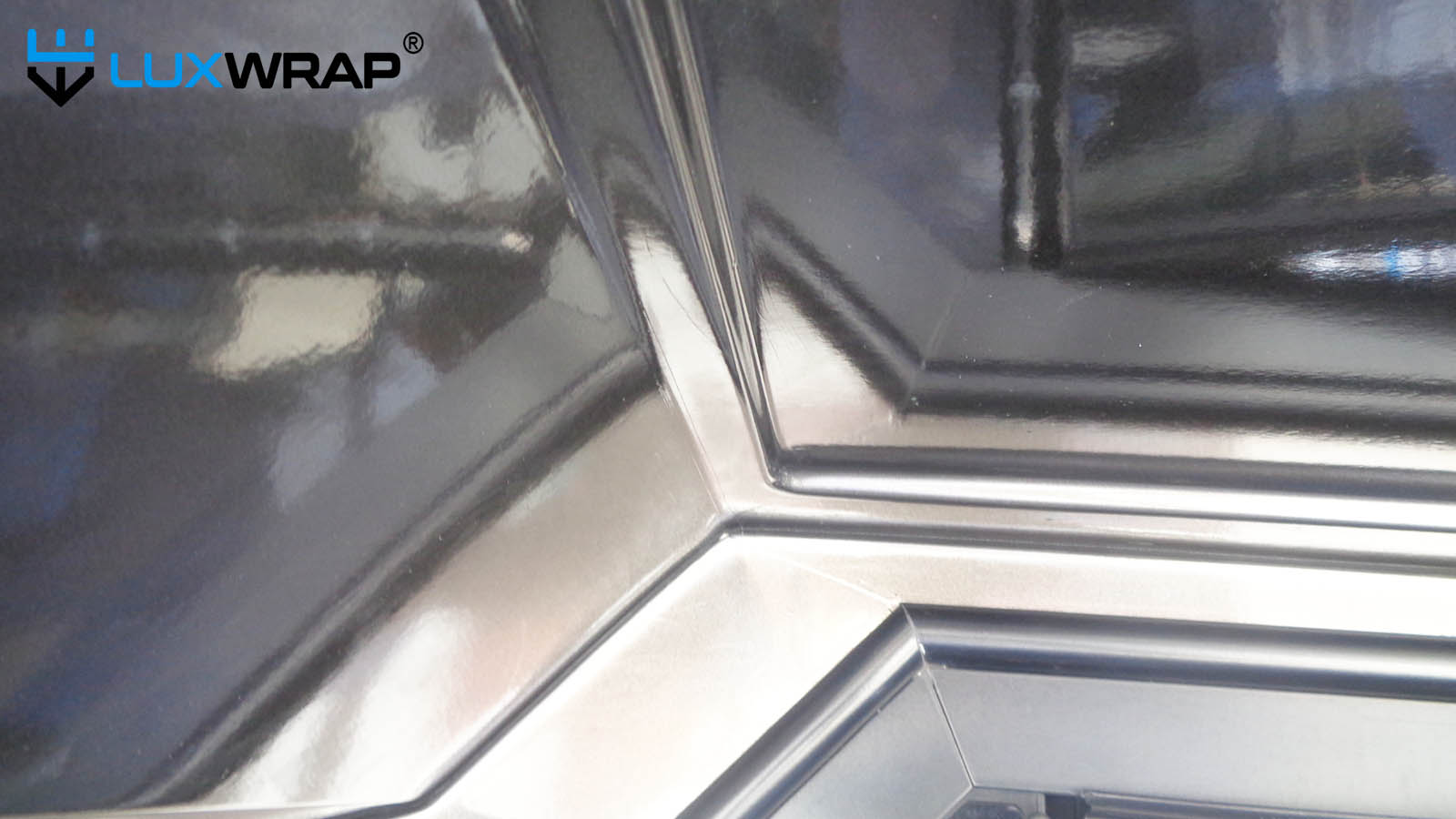

Vinyl Joins and Finish Quality - THE DEVIL IS IN THE DETAILS

Vinyl is a sheet product, which means joins are unavoidable. However, when installed correctly, they are executed with precision using specialist cutting tape designed to create clean string-line cuts, minimising use of blades.. This allows flawless results around curves, corners, and long straight runs.

Whilst head-to-head (butt) joins are technically possible, they are seldom practical on large surfaces. Vinyl naturally contracts over time, and butt joins risk opening, exposing a few millimetres of the substrate colour. To prevent this, all joins are overlapped by approximately 3–5 mm.

LuxWrap ensures joins are carefully hidden within the vessel’s natural lines,, and always finished as neatly as possible.

For owners and crew, the key point is expectation management: at professional standard, joins are virtually invisible from just a few metres away, preserving the overall seamless appearance of the wrap.

Exclusions and Special Areas

Non-slip surfaces are generally not wrapped, given their safety function. Whilst it is possible to put non-slip tape on top of the vinyl in small areas, we do not recommend it.

Where a major colour change is planned, owners may choose to:

- Paint non-slip areas to match the new scheme.

- Install artificial teak decking.

- Sand smooth any non-slip areas which are not needed.

One caution: if non-slip areas are painted after wrapping and then washed down, solvent residues can run over the vinyl, leading to permanent appearing many months later. In rare cases we have returned to re-wrap affected areas, underscoring the need for careful sequencing.

Ladder Areas & Metal Framework

- Painted ladders, tubular structures, and similar framework (e.g. above the monkey bridge leading to radars) are not viable for vinyl wrapping.

- If these need to match the superstructure colour, they must be painted — either before or after the wrap.

- Reminder: Painting after wrapping risks solvent runoff onto the vinyl, so crew must plan sequencing accordingly.

Scuppers

- Wrapping should stop at the vertical gunwale face; the scupper itself should be painted.

- If wrapped, adhesion and longevity cannot be guaranteed.

Cleanliness and Dust Control

Standing dust, overspray, and residues are frequent but avoidable problems. A clean, dust-free environment is essential for the highest quality results. Crew should ensure decks and adjacent areas are thoroughly washed down before wrapping.

After wrapping, it is equally important that the vinyl is maintained and kept clean. Vinyl is not designed to be left for months covered in dust with the sun baking into it, if this is allowed to happen then you should expect the vinyl in horizontal areas to age very quickly.

Cleaning itself should be done with water and soap, no abrasives should be used, and no solvent based cleaners.

Horizontal & Angled Surfaces

While vinyl offers a significantly lower-cost alternative to paint and can deliver years of service, owners and crew should be aware that horizontal and outward-facing angled areas of the superstructure will inevitably age more quickly, as they do with paint.

The rate of aging depends on multiple environmental factors:

- UV exposure (intensity and duration)

- Standing dust being left to bake into the vinyl in the sun.

- Vessel movement (whether the yacht remains stationary or travels regularly)

- Orientation (e.g., one side facing south for months, aging one side quicker)

- Water accumulation (standing water can act as a magnifier and accelerate degradation, and if combined with cleaning products can cause burning)

Maintenance Expectations — Horizontal & Angled Surfaces

Because exposure conditions vary, it is unrealistic to assign a fixed lifespan to every part of a superstructure wrap. In practice, the first signs of aging usually appear on horizontal or outward-facing sections, which may require re-wrapping after a couple of years, while the rest of the superstructure remains in excellent condition. These touch-ups are simple and can be incorporated into the vessel’s general maintenance schedule.

The key takeaway is expectation management: horizontal elements will demand attention sooner, but even with this periodic upkeep, the total cost remains only a fraction of repainting.

Material choice also plays a role. Metallic vinyls tend to weather faster than solid colours in horizontal applications, and performance can vary between manufacturers. For this reason, owners and managers should always rely on contractors with proven, real-world results using the specified material in comparable marine conditions.

Finally, durability on horizontal areas can be further improved with Paint Protection Film (PPF) such as NinjaShield®. Applying PPF to targeted sections reduces aging and provides an additional layer of protection against UV, standing water, and surface wear.

Summary

Superstructures, more than any other area of a yacht, are the first to show the effects of UV and weather exposure. Wrapping provides a practical and reliable way to restore or restyle appearance without the downtime or disruption of a paint programme.

Whether applied only to exterior faces or executed as a full superstructure project, the benefits are clear:

- Fresh gloss and colour uniformity.

- Protection of underlying paint systems.

- Minimal disruption to vessel operations.

Because superstructures involve complex curves, edges, and detailing, accurate quoting and consistent workmanship are critical—particularly on yachts over 40m. Many contractors underestimate the scope, struggle to deliver on time, or attempt to cut costs with unskilled labour. The result is poor finishes, extended delays, and ultimately higher costs to rectify mistakes.

By contrast, LuxWrap has reliably and routinely executed and delivered large-scale full superstructure wraps on schedule and to specification. Our proven processes and track record of successful projects ensure owners and managers can move forward with confidence, knowing the work will be done right the first time.

“This chapter and its contents are part of the eBook Yacht Wrapping Bible: The Ultimate Guide to Yacht Wrapping by LuxWrap® and are the intellectual property of LuxWrap Group Limited. References and link-backs are permitted; however, unauthorised duplication or reproduction or plagiarism, in whole or in part, will be treated as a breach of copyright and pursued through legal action.”

“This chapter and its contents are part of the eBook Yacht Wrapping Bible: The Ultimate Guide to Yacht Wrapping by LuxWrap® and are the intellectual property of LuxWrap Group Limited. References and link-backs are permitted; however, unauthorised duplication or reproduction or plagiarism, in whole or in part, will be treated as a breach of copyright and pursued through legal action.”

📞 Contact LuxWrap Today

Tel: +44 (0)208 068 7468

🌐 www.luxwrap.com

Chapter 3 — Deckheads, Wood & Accents

Three focused categories of yacht wrapping—deckheads, exterior wood refinishing, and accent wrapping —often involve small areas but deliver outsized impact. Each offers rapid transformation, minimal disruption, and a reversible path to styling changes.

Deckhead Wrapping

Painting deckheads usually means removal, shipping, paint shop time, and re-installation—a substantial undertaking for large square meterage.

Wrapping deckheads is straightforward: remove, wrap, refit. No shipping, no sanding, no dust. It is a category where wrapping almost always makes more sense than paint.

Wrapping also makes it easy to change finish—gloss to matt or satin, a subtle tone shift, or a material update—all reversible and efficient to maintain.

Why wrap deckheads?

- Clean, fast process with minimal disruption and mess.

- Consistent finish quality across large areas.

- Simple finish changes (matt/satin/gloss) without full paint cycles.

- Reversible and easy to refresh in sections.

Wood Refinishing (Exterior)

Refinishing can be interior or exterior; this section addresses exterior elements separate from hull and superstructure.

Gloss wooden fixtures—especially cap rails and flag staffs—often suffer significant UV degradation. On large yachts, sanding and re-varnishing hundreds of metres of wood is rarely practical mid-season, and even during a refit period, revarnishing is both time consuming and costly..

Wrapping provides a fast, convincing alternative. We can match woodgrains to existing finishes ensuring artificial and real wood sit seamlessly together. Over-laminating with NinjaShield® Surface & Paint Protection Film delivers a deep varnish-like sheen and added abrasion resistance—indistinguishable from fresh varnish at normal viewing distances, and accomplished with minimal downtime.

Benefits

- Rapid turnaround with minimal disruption to operations.

- Convincing woodgrain match and visual continuity with real varnish.

- Enhanced durability and gloss when protected with PPF.

- Reversible and maintainable in sections (localized touch-ups as needed).

- The larger the vessel, the greater the saving versus traditional paint/varnish cycles.

Accent Wrapping

Accent wrapping often means selectively styling external areas to modernise lines and sharpen definition. A common example is blackening the white panels between glazing to visually extend the windows, unifying the glass line and giving the yacht a longer, sleeker profile, but there are also several other objectives.

Typical objectives INCLUDE

- Unify and modernise window lines (blackout between glazing).

- Add contrast or texture to break up large white expanses.

- Highlight structural details for visual definition.

- Trial styling changes with a fully reversible solution.

Accents can also introduce texture or contrast—either with marine vinyl or architectural films where a tactile finish is preferred. Both approaches are proven on a wide range of vessels.

Technical notes

- As with any wrap, surface preparation governs finish quality and longevity.

- Joins are positioned along natural lines and finished to be unobtrusive from normal viewing distance.

- High-wear accent zones can be over-laminated with Paint Protection Film (PPF) for added durability.

Summary

Accent wrapping, exterior refinishing of discrete elements, and deckhead wrapping are high-impact, low-disruption interventions. They modernise profiles, restore tired surfaces, and simplify maintenance—often at a fraction of the time and cost of traditional methods.

“This chapter and its contents are part of the eBook Yacht Wrapping Bible: The Ultimate Guide to Yacht Wrapping by LuxWrap® and are the intellectual property of LuxWrap Group Limited. References and link-backs are permitted; however, unauthorised duplication or reproduction, in whole or in part, will be treated as a breach of copyright and pursued through legal action.”

📞 Contact LuxWrap Today

Tel: +44 (0)208 068 7468

🌐 www.luxwrap.com

Chapter 4 — Yacht Interior Wrapping

Yacht interior wrapping is a concept many owners, captains, managers, and crew are either unaware of, or only vaguely familiar with. In simple terms, it involves applying specially designed architectural films — such as 3M DI-NOC — to transform interior finishes. These films are tough, resistant to wear and knocks, and designed as permanent finishes, though they can be removed if required.

As with any type of wrapping, there are different customer profiles — from owners of older yachts to new builds — and the scope of work varies greatly depending on the situation.

Quick Facelift

A customer requiring a quick facelift typically has an older yacht or a vessel with an interior that no longer suits their taste — perhaps it feels too dark, dated, or simply not in line with their vision.

A traditional refit can mean months of downtime, sanding, solvents, mess, multiple contractors, and significant cost, many times that of wrapping. By contrast, a wrapping facelift avoids disruption, reduces expense, and delivers results quickly.

In these cases, owners typically want to retain some original aspects of the woodwork, but prefer to refresh large surfaces like doors faces and wall panels. Wrapping selected areas creates a brighter and modernised two-tone effect, dramatically lifting the look and feel of the space without the cost, downtime and mess of a full refit.

This type of work involves mostly flat surfaces, but still demands skilled installers. Low experience and poor technique can result in visible joins, bad cuts, or even damage to the original finish. The lesson is simple: experience matters. Going cheap usually proves costly.

In-Between Refresh

Some owners want to retain the original wood style and finishes, but face the challenge of UV damage or cloudy clearcoat. Instead of costly sanding and revarnishing, we can replicate the original grain with a carefully matched wood-effect film, and we can match the gloss (or even improve it) with high-grade surface protection films such as NinjaShield®.

The result is a refreshed interior that looks new at a fraction of the cost, and in fact much harder wearing due to the toughness of surface/paint protection film. This approach can be applied to specific surfaces, individual furniture pieces, or selected areas of the yacht. Whether the goal is subtle restoration or a striking transformation, the range of finishes and our expertise ensure results that feel authentic.

Full Interior Transformation

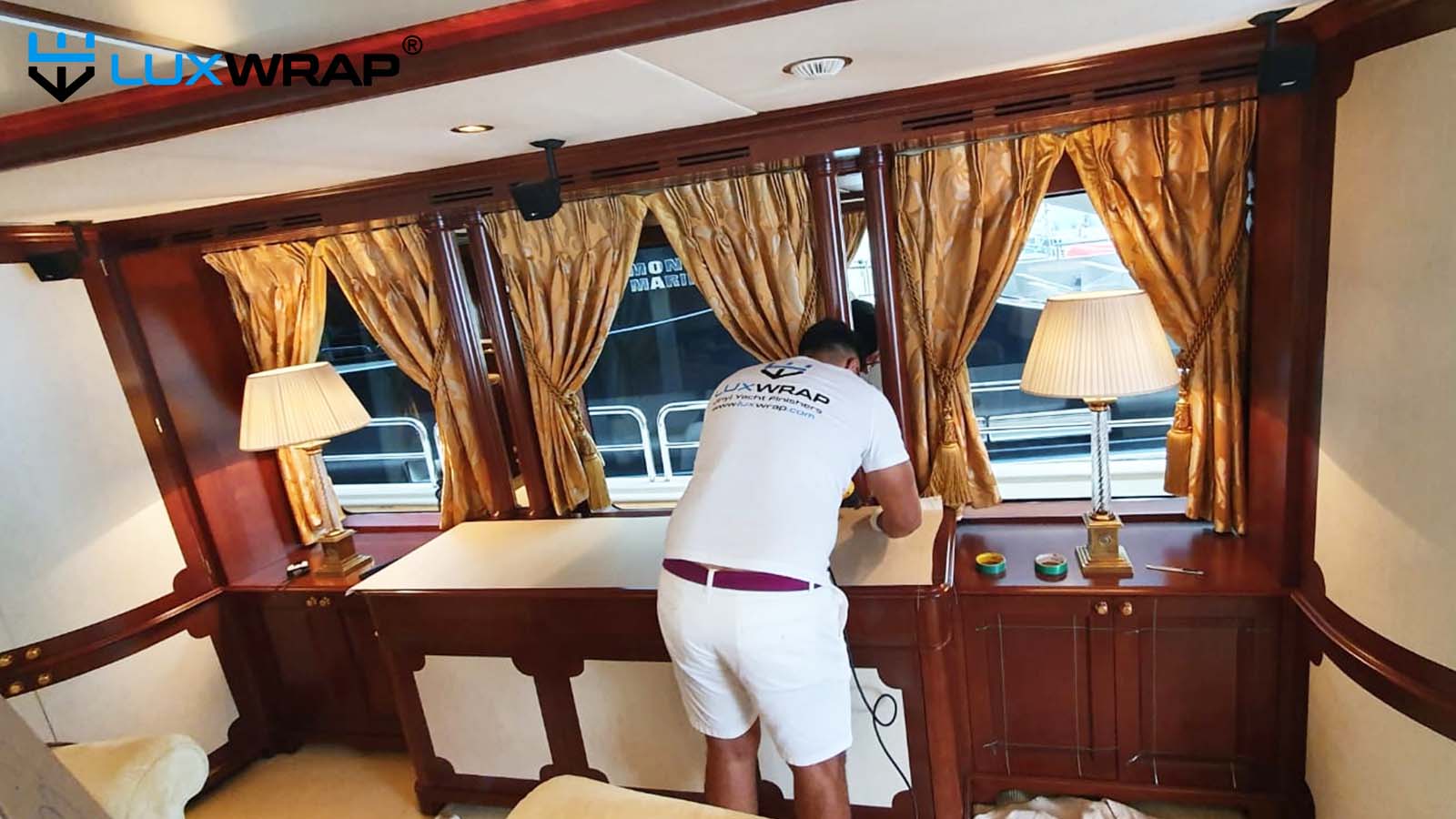

For owners — often those who have just purchased a yacht — who want a complete change, wrapping makes it possible to eliminate almost every trace of the original finish. Working with or without a designer, we can wrap wall panels, doors, furniture, and more in a wide variety of finishes.

From woods and metallics like gold and silver flake, to leather effects, textured textiles, and exotics such as alligator skin, the options are virtually limitless. We’ve carried out projects where the only original finish left visible was the inside of cupboards and drawers.

The benefit is not just creative freedom, but enormous time and cost savings: what normally takes months in a traditional refit can be achieved in weeks, or even days.

It is critical, however, to use expert installers who are experienced with architectural films. Wrapping yacht interiors requires far more skill than yacht hulls. due to the different material properties, extra thickness, different adhesive and complexity of the pieces to be wrapped.

Our approach ensures clear and transparent quotes, with professional workmanship backed by years of experience, track record of completed projects and warranty. Owners who want high standards should expect nothing less.

New Builds, Galley & Other Upgrades

Another growing area is wrapping on both new builds, and large yachts already in service — particularly in galleys, but also in corridoors and crew mess areas.

Mega yacht galleys are highly functional commercial grade spaces built from stainless steel for hygiene and practically endless durability. However, they often feel cold and dark due to the sheer amount of metal involved, and their position in the vessels lower decks means there is no natural light.

Wrapping changes that. By applying durable, knock-resistant architectural films to walls, doors, drawers, and appliances, we can transform these areas into welcoming, stylish spaces.

The films we use are not only attractive to look at, but practical: easy to clean, hygienic, and rated for long-term use. Transformations can be completed in a matter of days, without dust, solvents, or disruption.

The impact is remarkable — even seasoned galley fabricators and designers are often surprised by the realism of the finishes and the scale of the transformation. For older galleys with scratched stainless steel, we can restore the look completely with stainless-effect films that perform like the originals.

(In the next chapter we will also discuss wrapping galleys Paint & Surface Protection Film. )

Surface Preparation

Existing paint or clear coat

- If the clear coat is intact (not peeling or flaking), the vinyl can be applied directly.

- If the clear coat is peeling/delaminating, sand back to a sound surface and prime to provide a suitable base for adhesion.

Other surfaces (e.g., stainless steel/FIBERGLASS)

No preparation is required beyond removing any handles or necessary fixtures.

In Summary

Yacht interior wrapping offers flexibility, speed, and value that traditional refits cannot match. From quick facelifts to full transformations, from subtle woodgrain refreshes to bold new aesthetics, the possibilities are endless. Done correctly, it saves time, reduces cost, and ensures the interior is to the owner's taste.

“This chapter and its contents are part of the eBook Yacht Wrapping Bible: The Ultimate Guide to Yacht Wrapping by LuxWrap® and are the intellectual property of LuxWrap Group Limited. References and link-backs are permitted; however, unauthorised duplication or reproduction or plagiarism, in whole or in part, will be treated as a breach of copyright and pursued through legal action.”

📞 Contact LuxWrap Today

Tel: +44 (0)208 068 7468

🌐 www.luxwrap.com

Chapter 5 — Surface Protection Films (PPF/SPF/MPF)

Why Surface Protection on Superyachts?

Modern marine surface-protection films—variously termed PPF, SPF, or MPF—are transparent thermoplastic polyurethane (TPU) laminates with hydrophobic, self-healing topcoats. These versatile and highly utilitarian films protect paint and other surfaces, shed water and fingerprints, recover from moderate scuffs with ambient temperature or gentle heat, and are available in gloss, satin, or matt to match the design intent.

Crucially, they are reversible: at end of service life the film is removed and replaced, leaving the substrate intact. LuxWrap deploys these films at scale on both new-builds and delivered vessels to improve hygiene, reduce cleaning load, and preserve high-value finishes across interior and exterior zones.

Increasingley used on bothyacht interiors and exteriors, the following highlights the primary applications and typical works requested by vessels:

- Galley PPF Wrap

- Yacht Hull & Superstructures

- Varnished Wood & Marble

Galley PPF Wrapping

Large-yacht galleys are predominantly fabricated in stainless steel and are delivered in polished state. From handover however, it is normal for them to get knocked, scraped, degreased and scrubbed daily—exactly like any commercial kitchen. This constant cleaning and wear-and-tear inevitably marks the steel; despite the name, stainless can become visibly tired and unsightly over time.

PPF establishes a sacrificial surface that keeps the stainless beneath looking new, simplifies wash-downs, and improves overall hygiene standards—critical on large yachts with upwards of 30 crew onboard at any given time, and where guest and crew food-preparation areas are “restaurant-like” busy.

Scope Definition

As with any wrapping project, protecting a superyacht galley with PPF is not a “one-size-fits-all” exercise. The scope and scale of a galley PPF wrap can vary significantly. Below we set out the typical levels of depth that head chefs and interior managers, captains and management should be aware of, in order to know precisely what to look for when obtaining quotations.

Galley Level 1 — Face Surfaces Only

Some vessels focus on protecting only the obvious vertical face surfaces to keep them easy to clean and free from scratches. In practical terms this means wall surfaces, plus door and drawer faces, but not the edges of doors and drawers.

In this scenario the edges remain unwrapped and the installation is relatively quick and straightforward, with a correspondingly lower cost because the work is faster and does not require removal of doors or handles, nor cutting and folding the film around corners to the sides of the doors.

Where cost saving and speed are required—and the main objective is utility rather than comprehensive coverage (and its associated cost)—this is a sound approach. Removing handles from cupboard and drawer faces wherever possible will always lead to a better result.

Galley Level 2 — Face Surfaces & Edges

The next level of galley PPF wrap includes everything described above, plus the edges of all drawers and doors also being wrapped. This is the most commonly requested specification. Chefs and managers involved in this type of installation should understand that doors, handles, and associated hardware will need to be removed and reinstalled. LuxWrap has extensive experience with this workflow; even so, it is always helpful if the vessel’s engineering crew can be on hand to assist with removal/refit to maintain pace.

On smaller galleys, everything is cut by hand, which as you can imagine requires cutting the piece of material to the exact shape of the door, including the edge returns, and then hand-cutting and forming every corner.

On larger galleys—where the project scope and efficiency justify it—we bring a digital plotter cutter to site and produce templates for every door and panel, so that almost every single piece of PPF installed is precisely pre-cut before installation. This level of quality is a clear step above purely hand installation and can fairly be described as a “factory finish”.

Extractors

For the purpose of this eBook, extractor units deserve their own short section. In most cases, when we are delivering a Level 1 or Level 2 galley wrap, the chef elects to include the extractor exterior faces—i.e., those facing into the galley work area—while excluding horizontal tops and the interior faces that are not normally seen.

In some cases, however—particularly on very large, brand-new vessels—it is possible and sometimes requested to wrap the entirety of the extractors, interior and exterior. There is a considerable added expense, and one could argue that wrapping the internal faces behind the air vents is unnecessary as they are not seen. However these are precisely the areas with the highest grease build-up over time; accordingly, some vessels with visionary chefs and an appropriate budget choose to wrap the extractor units inside and out.

The scope of works to wrap inside an extractor is, obviously, highly detailed and delivered in confined spaces. In such scenarios we typically rely on digitally pre-cut components to ensure a repeatable, factory-grade finish.

Galley Conclusion

It is fair to say that the size, scale, level of detail, and budget of the vessel for the given works, have a direct bearing on the level of skill required by the wrap contractor and on the actual execution cost. It is therefore important for chefs, captains, and management to understand these different levels of scope, so that quotations are compared like-for-like when engaging a contractor.

Define your goals precisely, document inclusions and exclusions up front, and engage a contractor with the proven capability to deliver the specified scope to a consistent standard.

Other surfaces to be continued...

“This chapter and its contents are part of the eBook Yacht Wrapping Bible: The Ultimate Guide to Yacht Wrapping by LuxWrap® and are the intellectual property of LuxWrap Group Limited. References and link-backs are permitted; however, unauthorised duplication or reproduction or plagiarism, in whole or in part, will be treated as a breach of copyright and pursued through legal action.”

📞 Contact LuxWrap Today

Tel: +44 (0)208 068 7468

🌐 www.luxwrap.com