Interior & Exterior Yacht PPF Surface Protection

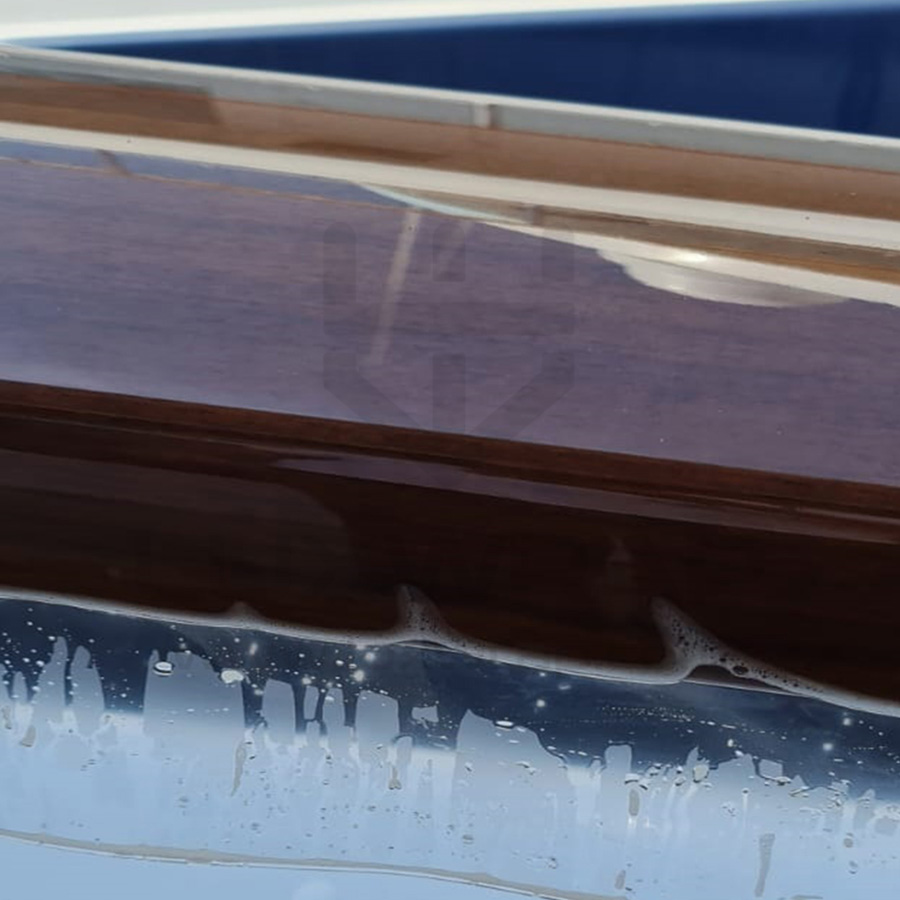

At the heart of our expertise is the installation of Paint Protection Film (PPF)—also referred to as Surface Protection Film (SPF) or Marine Protection Film (MPF)—on the interiors of mega-yachts, both new builds and delivered vessels.

Our film solutions deliver unmatched hygiene, durability, and effortless maintenance across a wide range of onboard spaces, helping preserve finishes while elevating the yacht experience.

What Our Projects Typically Include

Complete coverage of high-wear zones such as galleys, cold rooms, crew laundry facilities, elevators, cap rails, fridges, washer/dryer units, handrails, and mess areas.

Stainless steel protection: A discreet yet vital upgrade that keeps surfaces looking pristine and simplifies upkeep.

Large-scale application: We’ve wrapped entire galley suites and crew areas, applying PPF across hundreds of square metres for long-term durability.

Project Examples:

120m+ – Stainless steel protection across multiple galleys and crew areas, cap rails.

120m+ – Complex digitally cut PPF install, Crew & Owner Galleys, Extractors, Laundry, Worktops.

115m – Marble surfaces, Fridges and Appliances

100m+ – Hull protection, to resist UV/abrasion and extend repaint cycles.

120m+ – Triple-finish interior scheme: PPF used across high-touch surfaces.

110m – Garage doors and hull areas, to resist UV/abrasion and extend repaint cycles.

What is PPF / SPF / MPF?

Often referred to interchangeably, this high-performance material is made from Thermoplastic Polyurethane Elastomer (TPU), formed into a flexible, transparent film with self-healing properties and a hydrophobic coating.

- Hydrophobic – Repels water, making surfaces extremely easy to clean.

- Self-healing – Scuffs and scratches disappear with the application of a small amount of heat.

- Flexible application – Available in Gloss, Matt, and Satin finishes to suit every aesthetic.

Where is Paint Protection Film used?

External Applications:

- High-traffic deck areas

- Varnished cap rails and furniture

- Glossy table-tops and UV-exposed surfaces

- Tender scuff areas and fender rub points

- Exhaust zones to prevent carbon build-up

Internal Applications:

- Stainless steel galleys, fridges, and freezers

- High-gloss varnished wooden furniture

- Worktops, table-tops, marble

- Rails, handrails, and other high-contact zones

Why Choose PPF?

- Preserve surfaces: Maintain the look of new-build finishes.

- Enhance hygiene: Ideal for stainless steel galleys and food prep zones.

- Reversible: Like vinyl films, PPF can be removed and replaced.

Next Steps

Whether you are protecting stainless steel galleys on a new build or refreshing interiors on a delivered yacht, LuxWrap provides seamless installations at scale with results proven across multiple flagship projects.

Please contact us for a quote, or to discuss the suitability of your required application.